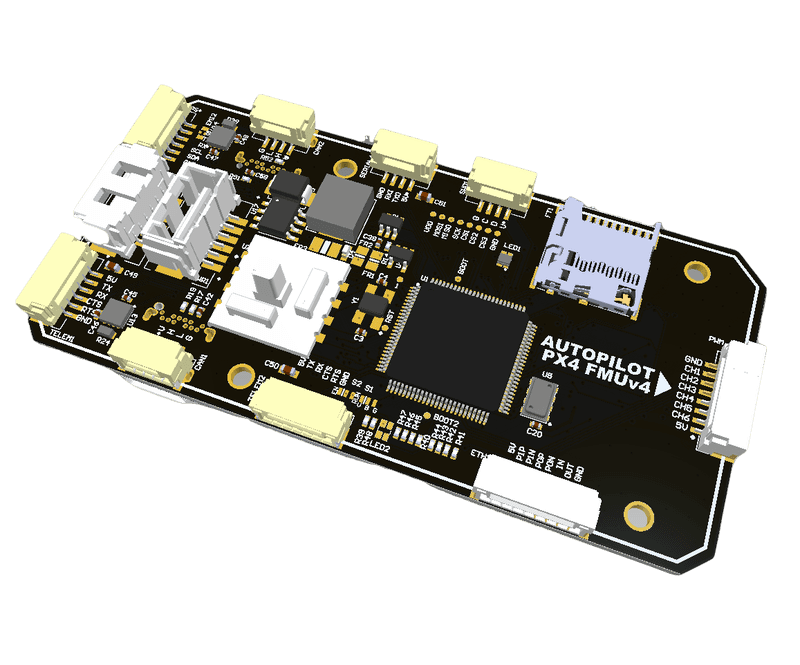

# Autopilot FMUv4

# Getting started

# Basic Assembly

# 1. Hardware specification

# Features

- Full compatibility with the Pixhawk project (opens new window) FMUv4 design standard and uses the Connector standard (opens new window) and Pixhawk Connector Standard (opens new window) for all external interfaces

- Firmware-compatible with PX4 (opens new window)

- Allows users to develop own payload code on RPI CM4

- High precision magnetometer sensor

# Quick Summary

- Main FMU Processor: STM32F427VIT6

- On-board computer: RPI4 CM4 (opens new window)

- On-board sensors:

- 3-Axis Digital Compass, RM3100 (opens new window)

- Magnetoresistive Sensor X, Y, Z Axis, HMC5883L (opens new window)

- 3-axis gyroscope, accelerometer, magnetometer, MPU-9250 (opens new window)

- 3-axis gyroscope, and a 3-axis accelerometer, ICM-20608 (opens new window)

- 3-Axis Digital Compass, HMC5983 (opens new window)

- Barometric Pressure Sensor, MS5611 (opens new window)

- Interfaces:

- 6 PWM outputs

- 3 dedicated PWM/Capture inputs on FMU

- Dedicated R/C input for CPPM

- Dedicated R/C input SBus with analog / PWM RSSI input

- I2C, UART ports

- 2 CANBuses with serial ESC

- Analog inputs for voltage / current of 2 batteries

- Power System:

- Power: 4.3 - 5.4 V

- USB Input: 4.75 - 5.25 V

- Can be powered from CAN: 5.2 - 30 V

- Weight and Dimensions:

- Weight: XXX g

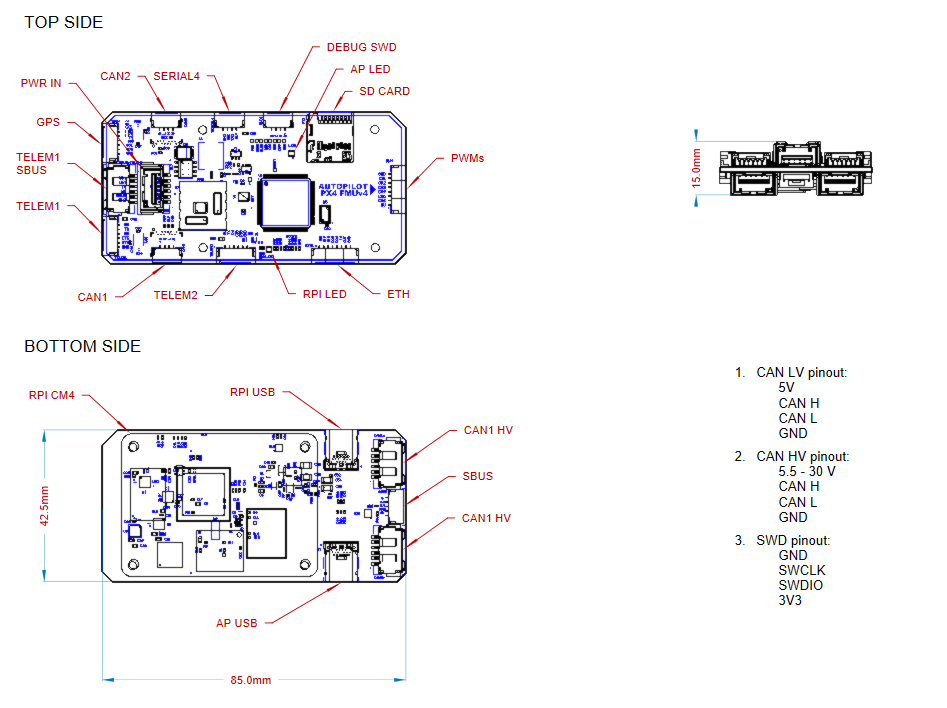

- Dimensions: 85 x 42.5 x 15 mm

- Operating temperature: -20 ~ 80°c(Measured value)

# 4.2. Wire

Schematic can be provided via e-mail request or issue on github.

Connectors

| № | Connector | Description |

|---|---|---|

| 1 | UCANPHY Micro (JST-GH 4) | Devices that deliver power to the bus are required to provide 4.9–5.5 V on the bus power line, 5.0 V nominal. Devices that are powered from the bus should expect 4.0–5.5 V on the bus power line. The current shall not exceed 1 A per connector. |

| 2 | 6-pin Molex (502585-0670 (opens new window), 502578-0600 (opens new window)) | Contacts support up to 100 V, 2 A per contact. But the board may work only with 2S-6S. |

| 3 | SWD | STM32 firmware updating using programmer-sniffer. |

| 4 | PWM1, PWM2, PWM3, PWM4 | Connectors should be used to deliver signal and power (below 1 amp) to payload such as SERVO or ESC (without power delivery) |

Here (opens new window) you can find manufacturer part number of connectors it self and its mates.

Pin configuration and functions

| Pin | CAN3 | Pin | CAN1, CAN2 | SWD |

|---|---|---|---|---|

| 1 | Vin | 1 | 5V in | GND |

| 2 | Vin | 2 | CAN High | SWCLK |

| 3 | CAN High | 3 | CAN Low | SWDIO |

| 4 | CAN Low | 4 | GND | 3.3V |

| 5 | GND | |||

| 6 | GND |

# 4.3. Specifications

Mechanical

Scheme is shown on the picture below.

| Width, mm | Length, mm | Height, mm | |

|---|---|---|---|

| Outline | 85 | 42.5 | 15 |

| PCB | 85 | 42.5 | 1.6 |

Total weight of device is XXX g.

You can download 3D model on GrabCAD (opens new window)

Housing

Information about case presented here.

Absolute Maximum Ratings

| Parameter | MIN | MAX | UNIT |

|---|---|---|---|

| Vin (CAN1) | 5.5 | 55* | V |

| V (CAN2, CAN3) | 4.5 | 5.5 | V |

| I max | A | ||

| Operating temperature |

*Noted Voltage should be delivered only with current limitation under 2.5 Amp.

Recommended operating conditions

| Parameter | Value | UNIT |

|---|---|---|

| Vin (CAN3) | 30 | V |

| V (CAN1, CAN2) | 5 | V |

| I max | A |

ESD ratings

| Description | Value | UNIT |

|---|---|---|

| Human-body model (HBM) | 2000 | V |

| Charged-device model (CDM) | 500 | V |

# 4.4. Description

Functional Block Diagram

Connection example diagram

# 4.5. Power Supply Recommendations

Device is designed to operate from an input voltage supply range between 4.5 V and 5.5 V over CAN2 or CAN3 connector, or 5.5 - 30 V from CAN1. This input supply must be able to withstand the maximum input current and maintain a stable voltage. The resistance of the input supply rail should be low enough that an input current transient does not cause a high enough drop that can cause a false UVLO fault triggering and system reset. The amount of bulk capacitance is not critical, but a 47-μF or 100-μF electrolytic capacitor is a typical choice.

# 4.6. Revision history

| version | Description |

|---|---|

| v1.1.0 | |

| v1.2.0 |

# 2. How to load a firmware

- If your device doesn't have a bootloader, you need to initially load it . Connect a programmer to the SWD connector of the autopilot and load the bootloader into 0x8000000 address:

st-flash write ~/PX4-Autopilot/boards/px4/fmu-v4/extras/px4_fmu-v4_bootloader.bin 0x8000000

The board should start to blink with orange color.

- Then connect the autopilot via USB, build the project for fmu-v4 and upload the firmware:

cd ~/PX4-Autopilot

make px4_fmu-v4_default upload